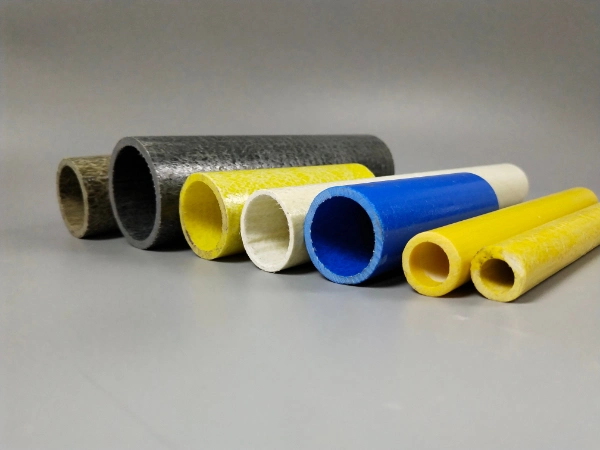

High Strength Fiberglass Composite Material FRP Pultrusion Profile Round Tube

Basic Info

| Model NO. | LTZ |

| Shape | Customized |

| Type | Profiled |

| Sample | Available |

| Standard | ISO |

| Feature | Light Weight, High Strength, Anti-Corrosion |

| Transport Package | Box or Tray |

| Specification | Customized |

| Trademark | Longtime |

| Origin | Hebei, China |

| Production Capacity | 10000meter/Day |

Product Description

FRP Pultruded profiles are widely used as structures in the chemical and corrosion resistance industry, cooling tower, parking lots, sidewalk of bridge, farming shed and so on.

Series of our pultrusion profiles include square tube, rectangular tube, round tube, angel, I-beam, Channel, rod and other custom profiles. After proper combination and connection, they could be widely used in many fields such as: FRP grating platforms, Walkways, ladders, guardrails, supporting structures of cooling tower, sporting profiles, tool handles and other load structures, etc.

LONGTIME FRP PRODUCT CO., LTD is specilized in FRP profiles, besides FRP tube, we supply FRP rod, sheet, I-beam and so on.

Specification

| Type | grp glassfiber Pultrusion FRP Square Tube |

| Material | ECR Glass Fiber + Resin (ORTHO,ISO,VE,PHENOLIC)+Filling (ATH) |

| Size | Can be customized |

| Color | According to RAL Book.Yellow, Orange, Blue, Green, Grey, etc. can be cutomized |

Production Process

Production process is a continuous production process to produce fiber-reinforced polymer profiles of any length and constant section. Reinforcement fibers may be roving, continuous mat, woven roving, carbon or others.

The fibers are impregnated with a polymer matrix (resin, minerals, pigments, additives) and passed through a pre-forming station that produces the stratification necessary to give the profile the desired properties. After the pre-forming step, the resin-impregnated fibers are pulled through a heated die to polymerize the resin.

Feature

>> Exceptional Strength: reduce damage caused by accidental collisions>> Light Weight: Weighing up to 80% less than steel and 30% less than aluminium>> Corrosion Resistant: unaffected by exposure to a wide variety of corrosive chemicals and environments>> Maintenance Free: The corrosion resistant properties remove the necessity of periodic painting or surface treatment.>> Low Thermal Conductivity: around 1/250 of aluminium, and 1/60 of steel>> Non Conductive: electrically non-conductive, ideal for cable trays, ladders, platforms>> Electromagnetic Transparency: transparent to radio waves, microwaves and other electromagnetic frequencies>> Dimensional Stability: resistant to stretching, warping, or swelling over a wide range of temperatures & physical stresses>> Thermal Stability: withstanding continuous exposure to temperatures of up to 65 degrees centigrade>> Easy to install and maintain >> Rich color: there are many colors for you to choose

Package & Shipment

Related Products

Why Choose Us? 1.Highest qualityWe are the manufacturer who adopts imported raw materials to guarantee the high quality.2. Most competitive priceWe can adjust the price according to your market demand changes, and also can launch a series of promotional activities in a bad economic environment.3. ProfessionalWe have a complete team, including development, procurement, production, inspection, sales and after-sale service. 4. Best serviceWe would give feedback within 24 hours. For any question or problem, we would try our best to help. Trust, High quality and Best service build long term win-win business.

FAQQ: Are you trading company or manufacturer ?

A: We are a professional manufacturer with export certificate.

Q: What is your delivery time?

A: Generally it takes about 5-10 days if the goods you need are in stock as we just only need some time to pack the goods as the customer's request. Otherwise it takes about 15-20 days to arrange production and packing. If customers request customization the special size, it would take more time

Q: Do you provide samples?

A: Yes, we could offer the sample for free charge, but do not pay the cost of freight.

Sample is available. Customization is accepted. Welcome your inquiry, we would give feedback within 24 hours.