Gfrp Epoxy Resin Fiberglass Rebar

Basic Info

| Model NO. | 20mm |

| Customized | Customized |

| Color | Multi-Color |

| Surface Treatment | Unfinished |

| Forming Way | Pultrusion |

| Shape | Twist |

| Type | Concrete Reinforcement |

| Transport Package | Normal |

| Specification | Nominal diameters should range from 6mm to 36mm |

| Trademark | LEADFPR |

| Origin | China |

| HS Code | 3916909000 |

| Production Capacity | 500 Tons Per Month |

Product Description

GFRP RebarGlass fiber reinforced bar is made of high performance glass fiber, epoxy resin, curing agent and other materials, using appropriate

molding curing process composite steel;The high performance fiber is the reinforcing material and the epoxy resin is the matrix

material.Fiber has a very high tensile strength, is the main provider of the strength of glass fiber reinforcement, mainly to bear the load,

the matrix material has the role of bond, transfer shear, its physical properties can affect the physical properties of fiber reinforcement

materials.

Product features

• Non corrosive, never rusty, heat insulation, non-conductive, antimagnetic wave

• It is 25% of the weight of the steel bar, easy to place

• The tensile strength is 1.5-2 times higher than the reinforcement, and the pull-out resistance is increased by 30% compared with the reinforcement

• 100% corrosion resistance to alkali and acid environments

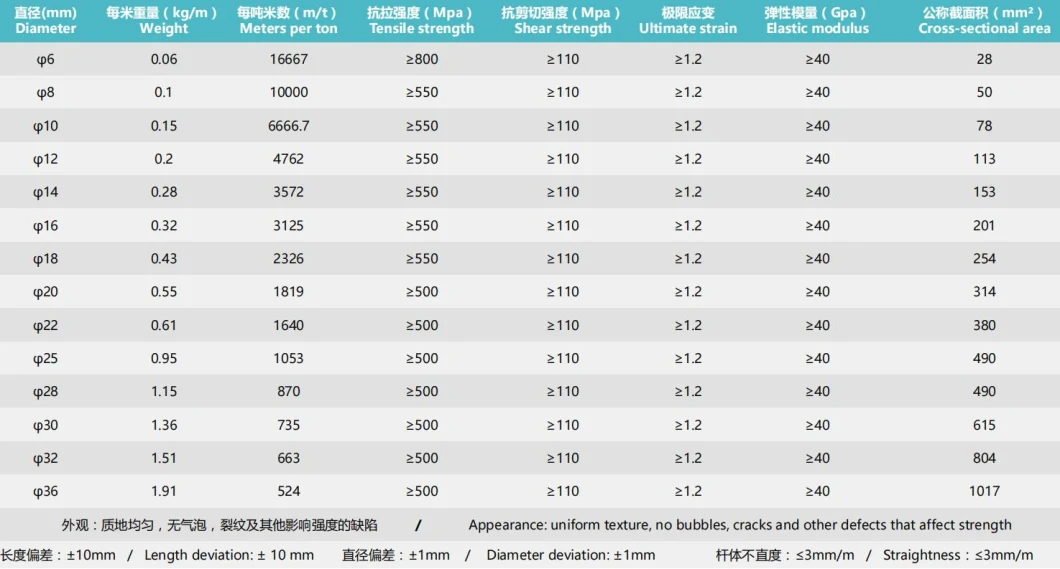

Common models and technical parameters

Common models and technical parameters

· Nominal diameters should range from 6mm to 36mm, and the nominal diameters of commonly used fiberglass bars are 20mm, 22mm, 25mm, 28mm and 32mm. · The density of fiberglass material is between 1.9g/cm3 and 2.2g/ cm3. · Follow the design code: [China JT / t406-2003 glass fiber reinforced bars for civil engineering]Comparison of fiberglass and steel

•Usage: GFRP is basically similar to steel bar in performance. It has good bond with concrete, high tensile strength and low shear strength. It can be easily cut directly by composite shield machine without causing abnormal tool damage.• In terms of construction period: GFRP shape is directly customized, which reduces the processing steps of ordinary steel bars,while lapping replaces welding process, which saves the time of making the cage.

Strength: the tensile strength of steel bars is 300-500mp, the tensile strength of GFRP is 600-800mp, and the tensile strength of fiberglass bars is better than ordinary steel bars, which is 20% higher than the steel bars of the samespecification • Connection: steel can be welded, glass fiber with u-buckle lap • Special purpose: glass fiber reinforcement for non-conductive, diamagnetic wave, machine room, CT room and other building glass fiberreinforcement;In terms of construction safety: GFRP cage continuous wall can be directly penetrated by shield tunneling machine, which can avoid dangerous situations such as mud, water and sand, save the cost of breaking down the continuous wall, and reduce dust and noise pollution at the same time. • In terms of economy: compared with ordinary steel bars, GFRP is lighter, thus reducing the production cost of the cage. At the same time, due to the large glass fiber cage, it reduces the width of the continuous wall, saves the numberof continuous wall interface i-steel or lock pipe, and saves the costCorrosion resistance: as time goes on, steel bars will corrode, resulting in the maintenance of the project. However, GFRP is a new type of green environmental protection reinforcement material widely used in high-performance reinforced concrete (cement).