FRP Rod Fiberglass Rod ECR Core Rod Epoxy/Corrosion Materials for Insulators

Diameters: 5 12 13 14 16 18 20 22 24 26 28 30 32 34 40 44 50 55 68 70 80 90 100 110 Company profile: Focusing on epoxy r

Basic Info

| Model NO. | Diameter 5 12 13 14 16 18 24 30 34 40 68 70 |

| Material | Fiberglass |

| Fiber Type | ECR |

| Type | Epoxy FRP |

| Transport Package | Crate |

| Specification | Epoxy resin and fiberglass |

| Trademark | MPC |

| Origin | China |

| HS Code | 8547909000 |

| Production Capacity | 3000 Ton/Year |

Product Description

Diameters: 5 12 13 14 16 18 20 22 24 26 28 30 32 34 40 44 50 55 68 70 80 90 100 110Company profile:

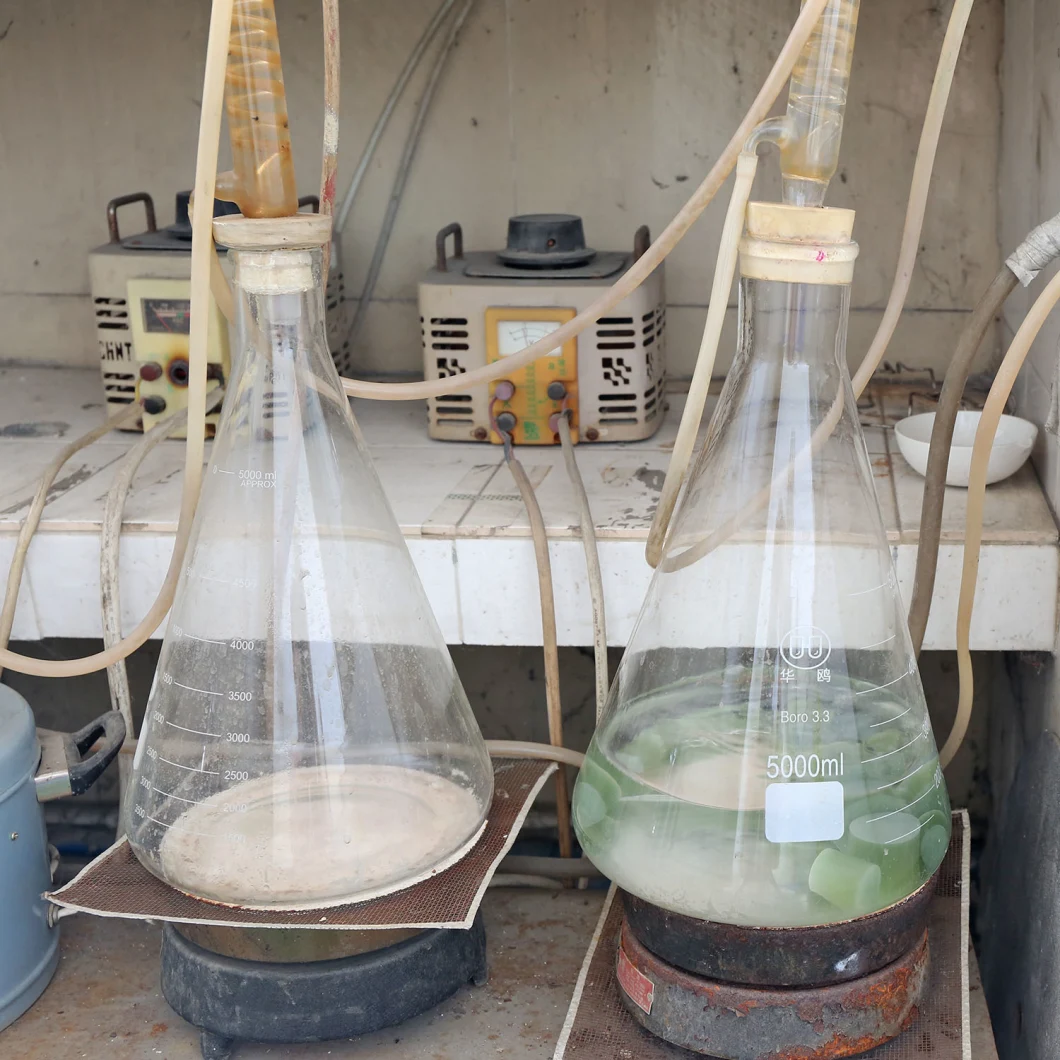

Focusing on epoxy resin fiberglass rod applied to composite insulator for 15 years. We are qualified supplier to China Southern Power Grid and State Grid of China. Our ECR rod has been sold to America, Iran, Brazil, Egypt, Indonesia, etc.

| No. | Property index | IEC61109 , DL/T1580-2016 standard requirement | Actual Value |

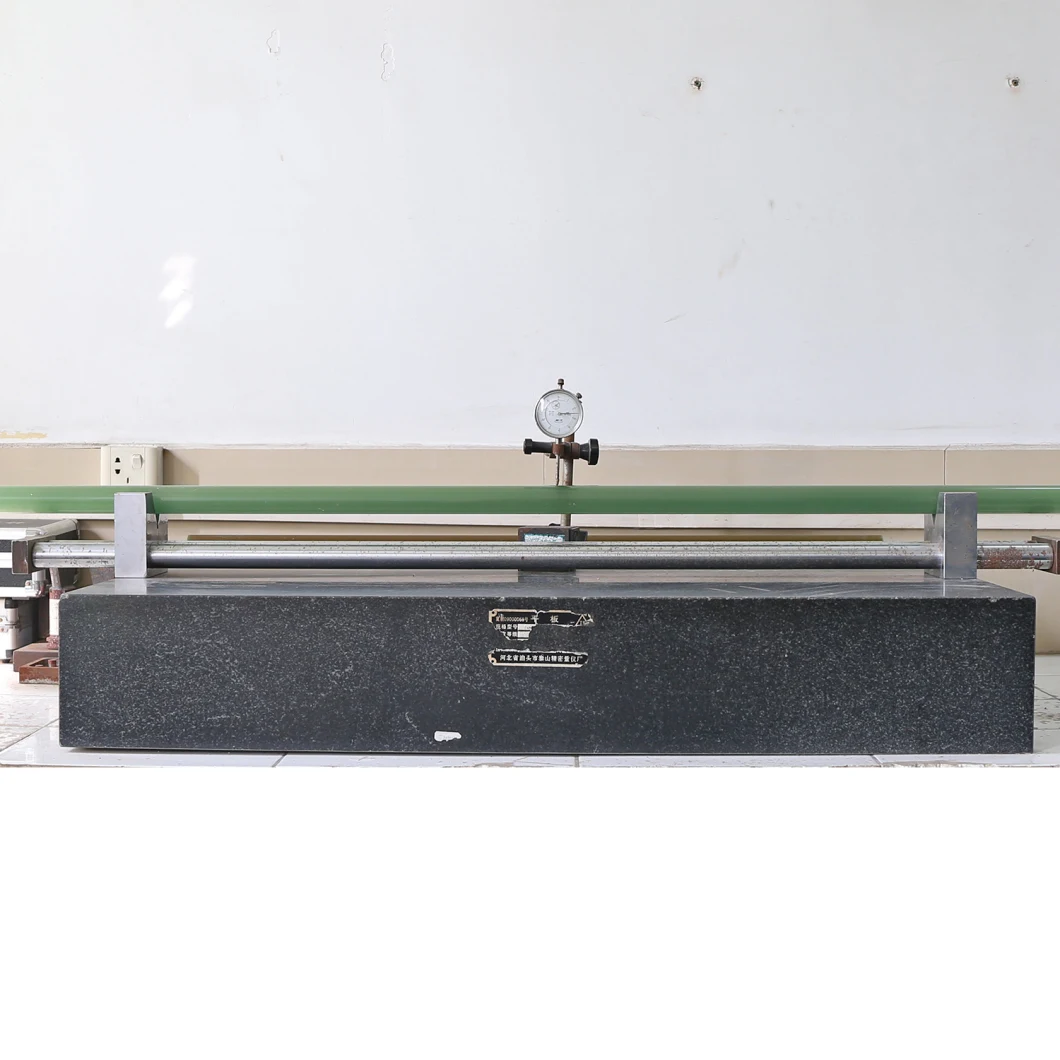

| 1 | Straightness | Length=1m,≤1.5mm | Length=1m, 0.8mm~1.2mm |

| 2 | Diameter tolerance | <= Φ30 mm: (+0.03~-0.02); >Φ30: (±0.03); | <=Φ30 mm: (+0.03~-0.02); >Φ30: (±0.03); |

| 3 | Roundness | Roundness <0.02 mm | Roundness <0.02 mm |

| 4 | Barcol hardness | 65~75 HBa | 68~72 HBa |

| 5 | Tensile strength | ≥1100MPa | 1180~1415 MPa |

| 6 | Bending strength | ≥900MPa | 950 ~1080MPa |

| 7 | Tearing Strength | >=35MPa | >=50MPa |

| 8 | Water absorption(20±2ºC,24h) | ≤0.05% | 0.006~0.028% |

| 9 | Dye penetration test | Test time: ≥15min, sample no penetration | Test time: >15min, sample no penetration |

| 10 | Water diffusion test | Leakage current less than≤50μA | Leakage current:18~35μA |

| 11 | Thermo bending strength Test temperature:150 ºC, Test time: 1h, Within 5 minutes | Thermo bending strength 300~350MPa | Thermo bending strength 300~350MPa; |

| 12 | Thermal induced performance test: Test temperature:150±2ºC, Test time: 4h, | No crack, no temperature variation (no surface discoloration). | No crack, no temperature variation (no surface discoloration). |

| 13 | Brittle fracture resistance test 1N HNO3, 80% SML withstand time=96Hrs | No Crack, no broken | No Crack, no broken |

| 14 | Electric puncture Strength | AC: >=30kV/cm DC:>=50kV/cm (+) | AC:>=50kV/cm DC:>=50kV/cm (+) |

| 15 | Power Frequency Withstand test 30minutes withstand at 80% of dry power frequency flashover voltage | No flashover, No Puncture Temperature increasing no more than 5K | No flashover, No Puncture Temperature increasing less than 5K |

| 16 | Dry lightening impulse withstand Voltage (+) | >=+100kV | >=+100kV |

| 17 | Volume Resistance (140ºC) | >=1×1010 (Ω.m) | >=1×1011 (Ω.m) |

| 18 | Anti-Swing Fratigue test 12×105 circle | No crack, No stress whitening | No crack, No stress whitening |

Send to us